-

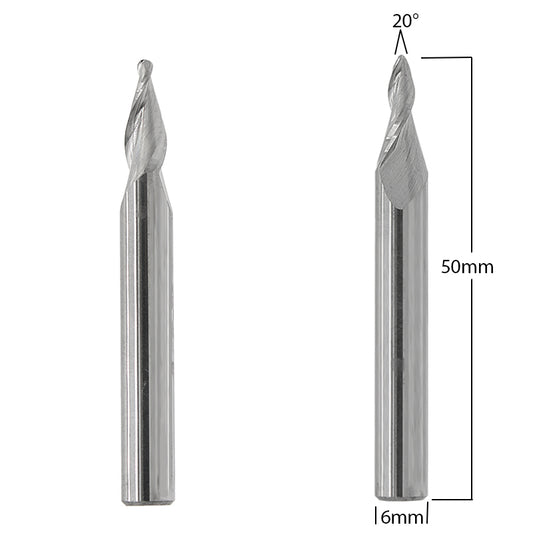

Tapered Ball Nose Router Bits for CNC Router

Regular price $20.00Regular priceUnit price perTapered Ball Nose Router Bits for CNC Router

Regular price $20.00Regular priceUnit price perTapered Ball Nose Router Bits for CNC Router

Regular price $20.00Regular priceUnit price per -

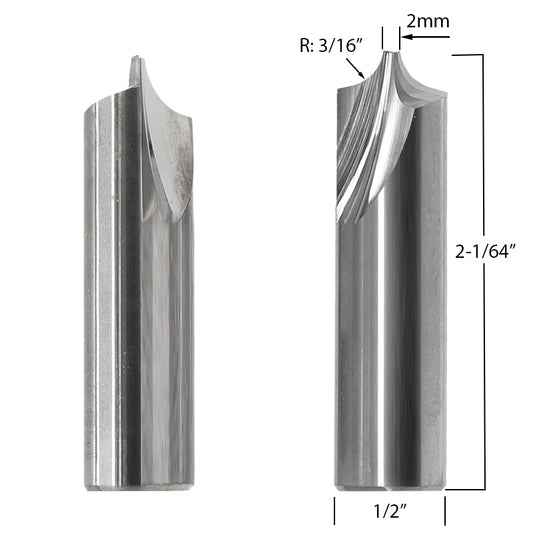

Inner R Corner Bits for CNC routers

Regular price $60.00Regular priceUnit price perInner R Corner Bits for CNC routers

Regular price $60.00Regular priceUnit price perInner R Corner Bits for CNC routers

Regular price $60.00Regular priceUnit price per -

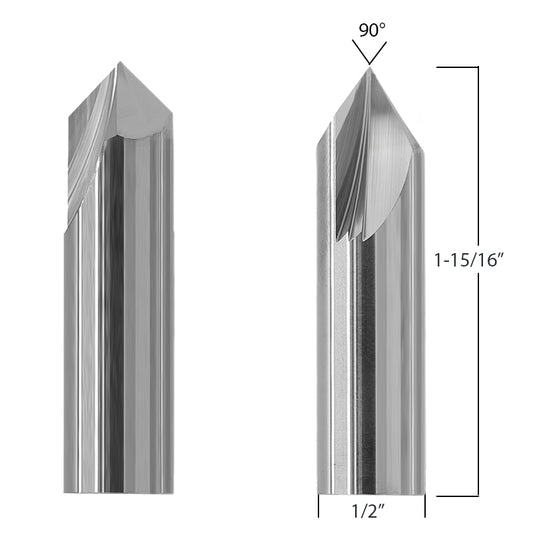

V-Groove Bits designed for CNC Routers

Regular price From $90.00Regular priceUnit price perV-Groove Bits designed for CNC Routers

Regular price From $90.00Regular priceUnit price perV-Groove Bits designed for CNC Routers

Regular price From $90.00Regular priceUnit price per -

Holder Clamps for Route Bits

Regular price $10.00Regular priceUnit price per -

Collets for ER20 Tool Holder for CNC Router Bits

Regular price $15.00Regular priceUnit price perCollets for ER20 Tool Holder for CNC Router Bits

Regular price $15.00Regular priceUnit price perCollets for ER20 Tool Holder for CNC Router Bits

Regular price $15.00Regular priceUnit price per -

Collets for ER25 Tool Holder for CNC Router Bits

Regular price From $15.00Regular priceUnit price perCollets for ER25 Tool Holder for CNC Router Bits

Regular price From $15.00Regular priceUnit price perCollets for ER25 Tool Holder for CNC Router Bits

Regular price From $15.00Regular priceUnit price per -

Collets for ER32 Tool Holder for CNC Router Bits

Regular price $20.00Regular priceUnit price perCollets for ER32 Tool Holder for CNC Router Bits

Regular price $20.00Regular priceUnit price perCollets for ER32 Tool Holder for CNC Router Bits

Regular price $20.00Regular priceUnit price per

Tool Operation Notices

-

Tool Selection

- Our brand’s tools are designed for professional users, with different tools created for different materials.

- They are mainly divided into five categories: particle board, MDF, solid wood, acrylic, and artificial stone.

- Professional users must select the appropriate tool according to the material to achieve the best cutting performance and durability, and to avoid tool breakage caused by excessive pressure.

- All tools are designed to rotate clockwise.

-

Balance Testing

- Every tool undergoes balance testing upon completion to ensure there is no runout.

- To further guarantee stability during use, please pay attention to selecting high-quality equipment and collets.

-

Collet Requirements

- Always use a collet of the correct size.

- If the collet is found to be out-of-round or worn, it will fail to properly clamp the tool.

- Replace immediately with a standard collet to avoid dangerous situations such as vibration, tool ejection, or breakage during high-speed rotation.

-

Tool Shank Installation

- Installation must comply with EU regulations.

- For example, a shank diameter of 12.7 mm must be clamped to a depth of 24 mm to ensure the tool shank can withstand the required pressure.

-

Speed Settings

- For tools with larger diameters, set the spindle speed according to the speed chart.

- Feed the tool forward slowly and maintain a uniform feed rate.

- Do not stop feeding during cutting, as this may damage the tool or workpiece.

- Suggested router speeds

Bit Diameter Maximum Speed 1” (25mm) 24,000 RPM 1-1/4" - 2” (30 - 50mm) 18,000 RPM 2-1/4” - 2-1/2” (55 - 65mm) 16,000 RPM 3” - 3-1/2” (75 - 90mm) 12,000 RPM

-

Tool Replacement

- When a tool becomes dull, replace it with a new one immediately.

- Do not continue using a worn tool, as this may cause tool breakage and workplace accidents.

-

Blade Length Selection

- Always select a cutting edge length greater than the workpiece depth.

- For example, to mill a groove with a depth of 12.7 mm, choose a tool with a cutting edge length of 25.4 mm.

- Avoid using tools with cutting edge lengths equal to or less than the workpiece depth.

-

Safety Precautions During Operation

- Operators must wear safety glasses and use safety push handles.

- When using tabletop machines, also install anti-kickback devices to prevent the workpiece from rebounding during high-speed cutting and causing accidents.